13 March 2017

Design and Production of industrial systems

13 March 2017

Design and Production of industrial systems

TAQA, the leading private electricity producer in Morocco, has contracted CNIM Babcock Maroc to manufacture and install front and back screens as part of the maintenance of a boiler in its power plant at Jorf Lasfar.

With a turnover of €380M, TAQA Morocco, a subsidiary of the TAQA Group, is the leading energy supplier in Morocco and to the Moroccan Office National d’Electricité et d’Eau Potable (ONEE – National Electricity and Drinking Water Bureau). The company accounts for 50% of the Kingdom's electricity production, and has the largest coal-fired power station in the country, with six production units.

With the aim of more efficient, more reliable production, Morocco's leading electricity producer is conducting a program of thorough maintenance on its generators. As part of that program, in early 2017, boiler 3 at the Jorf Lasfar Power Plant will be shut down for maintenance.

TAQA Morocco has chosen CNIM Babcock Maroc, a subsidiary of CNIM, because they offered an optimized technique, to be delivered within a strict timeframe. Two contracts were signed in 2015 and 2016, on the erection of the panels of screens, firstly to the rear and then to the front of the boiler.

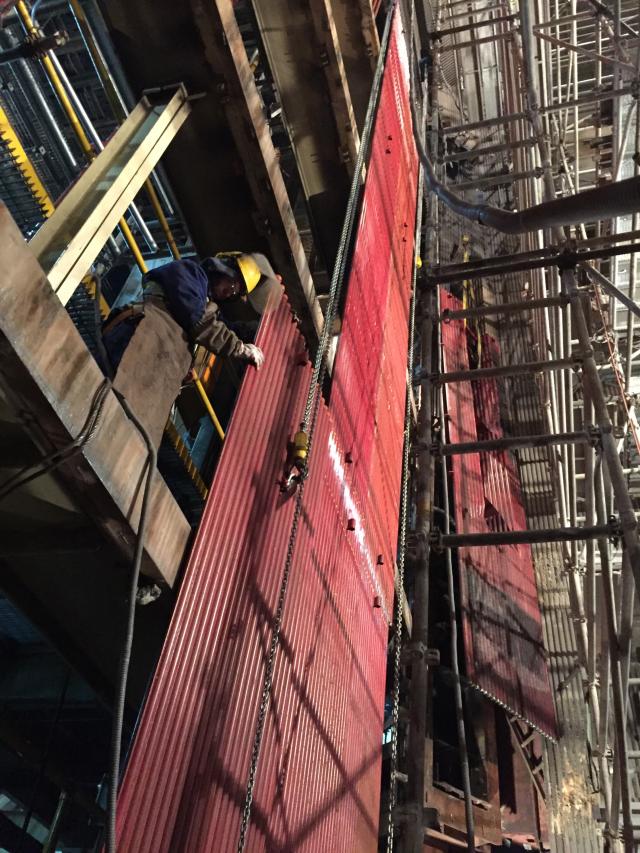

Over the course of a year, numerous specialist teams will play their part, for the preliminary studies and design of the equipment, prefabrication and on-site installation. The challenge lies in completely replacing large screens in an operational boiler, within a very short period of time: a first, which will require a great deal of technical expertise. These panels will be pre-made in a workshop and then inserted into the boiler using two support beams and winches, taking care not to disrupt the coactivity on the site.

Headquartered near to Casablanca, CNIM Babcock Maroc is one of CNIM Group three industrial sites, along with China and France. This site specializes in the manufacture of industrial boilers, heat exchangers and pressurized equipment. It also provides on-site services and industrial subcontracting for machine-welded parts. With 130 employees and 6000m² of workshop space, the company was set up in 1949, and became part of CNIM Group in 1990.